-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

Tumble Dryer

The drum dryer is an efficient and widely used drying equipment, mainly used to process various wet materials. Its main features and working principles are as follows:

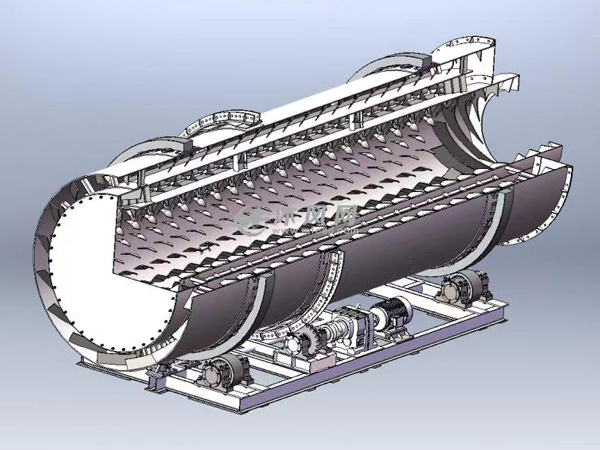

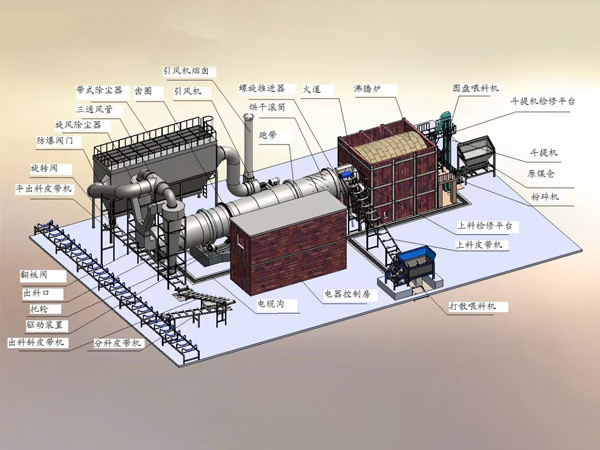

Structure and composition: The drum dryer is mainly composed of a rotating drum, an induced draft device, a high-speed scattering device, a lifting plate, a self-cleaning device, a transmission device, a conveying device, a hot air device, a reducer, a support device and a sealing device. These components together constitute a complete drying system.

Working principle: The drum dryer drives the drum to rotate through a motor, and the material tumbles in the drum. At the same time, hot air is blown in from the outside of the drum, directly in contact with the material, and the moisture in the material is evaporated. This direct hot air flow contact method can dry the material quickly and effectively.

Advantages: The drum dryer has the advantages of high efficiency, energy saving and environmental protection, wide applicability, and simple operation. Its hot air flow can directly contact the material to improve the drying efficiency; at the same time, the equipment itself can recycle heat and reduce energy waste. In addition, the drum dryer is suitable for drying a variety of materials, including powders, granules, blocks, etc., and can be adjusted according to the different amounts of materials.

Application range: Drum dryer is widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries, such as slag, limestone, clay, river sand, quartz sand, slag and other wet materials drying. At the same time, it is also suitable for drying materials in agriculture, feed, fertilizer and other industries.

In summary, drum dryer is a high-efficiency, energy-saving and environmentally friendly drying equipment with broad application prospects.

|

|