-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

River Sand Drying Machine

Working principle of river sand dryer

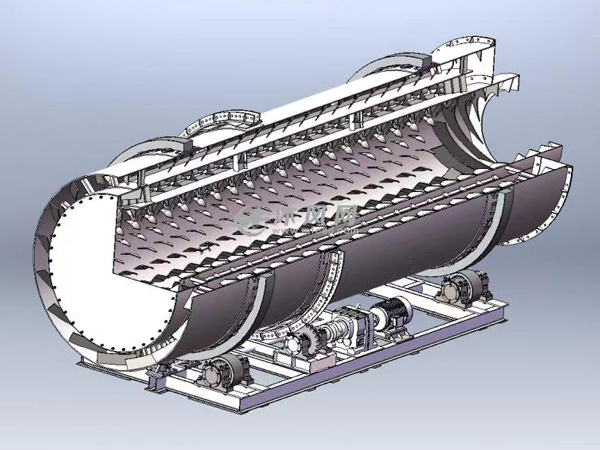

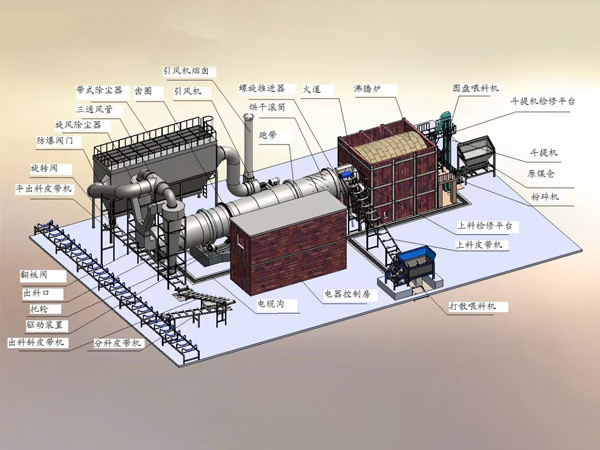

Power is generated by electricity, diesel, wind, flammable materials, etc., and the ambient air is used for heating, and then transported to the surrounding area to reach the appropriate temperature for dehumidification. The specific process is as follows: the wet material is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe of the hopper feeder. The slope of the feeding pipe should be greater than the natural inclination of the material so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder slightly inclined to the horizontal line. The material is added from the higher end, and the heat carrier enters from the lower end, in countercurrent contact with the material. There are also heat carriers and materials that flow into the cylinder together. As the cylinder rotates, the material moves to the lower end under the action of gravity. In the process of the wet material moving forward in the cylinder, it is directly or indirectly heated by the heat carrier, so that the wet material can be dried, and then sent out at the discharge end through a belt conveyor or a screw conveyor. A lifting plate is installed on the inner wall of the cylinder. Its function is to lift up and scatter the material, so that the contact surface between the material and the airflow becomes larger, so as to increase the drying rate and promote the material to move forward. The heat carrier is generally divided into hot air, flue gas, etc. After the heat carrier passes through the dryer, a cyclone dust collector is generally required to capture the material carried in the gas. If the dust content of the tail gas needs to be further reduced, it should also pass through a bag dust collector or a wet dust collector before being discharged.

Classification

Dryers can be divided into industrial and civil types. Industrial dryers are also called drying equipment or dryers. Civil dryers are a type of washing machinery. They are generally used to remove moisture from clothing and other textiles after water washing and dehydration.

There are several modes of drying machines, such as belt drying, drum drying, box drying, tower drying, etc.; the heat sources include coal, electricity, gas, etc.; the materials are dried in hot air airflow and radiation, etc. The hot air drum drying is that the hot air flow moves forward from the tail, fully contacts with the materials, and fully utilizes the heat transfer through heat conduction, convection, and radiation; the heat energy is directly transferred to the materials, so that the moisture of the materials is continuously evaporated in the cylinder, and the air induction device at the inlet draws out a large amount of moisture and wet air flow to prevent secondary pollution caused by dust discharge; the material movement is promoted through internal spiral stirring, sweeping, and copying to complete the entire drying process; countercurrent conduction dehumidification avoids reducing repeated drying procedures.

Features

The drying intensity is high. Since the materials are highly dispersed in the airflow, the entire surface of the particles is actively the effective area for drying. The drying time is short. The airflow dryer has a simple structure, small footprint, and is easy to build and maintain. The processing capacity is large and the thermal efficiency is high. When drying non-bound water, the thermal efficiency can reach 60%. The dryer achieves "zero horizontal thrust", greatly reducing the wear of the support rollers, and the cylinder runs smoothly and reliably; the dryer adopts a "self-aligning support roller device" so that the support roller and the roller ring are always in linear contact, which greatly reduces wear and power loss.

|

|