-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

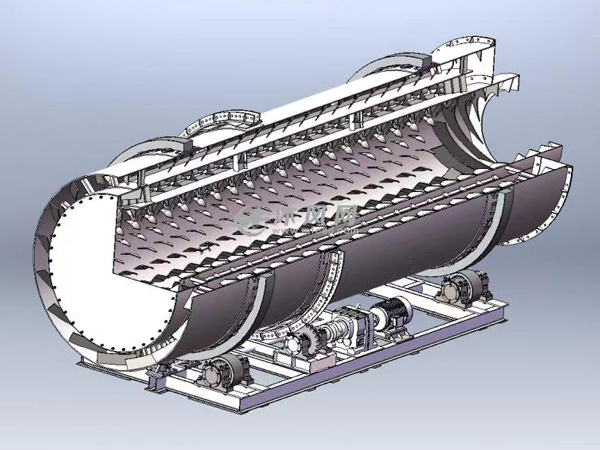

Pin Gear Three-Drum Dryer

SH type pin gear transmission three-drum dryer is a new generation of industrial rotary dryer independently developed by our company. It is mainly used for drying materials within a certain humidity and particle size range. It can be used for drying materials such as yellow sand (dry mortar), molding sand, slag, fly ash, bottom slag, clay and various coals. According to the requirements of different industries for the final moisture content of materials after drying, the moisture content of the materials after drying can reach less than 0.5%. The overall structure of the product is compact and occupies a small area. The cylinder transmission is stable, the energy consumption is low, and it is easy to maintain in the later stage. The drying efficiency is high and the energy-saving effect is obvious. It is widely used in cement, casting, building materials, metallurgy and chemical industries. Its main advantages:

1. It overcomes the disadvantage of easy slippage of traditional three-drum dryers and has high output. Ordinary three-drum dryers use the friction between the belt and the supporting wheel to drive the rotation of the cylinder. When the weight of the material inside the dryer is too large and the equipment is started, the belt and the supporting wheel will slip and the dryer cannot operate normally. If the equipment is suddenly stopped and restarted, slippage will also occur. FSTH (xl) type pin-tooth transmission three-drum dryer adopts single motor transmission to avoid such phenomenon.

Ordinary three-drum dryers adopt friction transmission, and the drum speed is generally set at 5-7 rpm, which cannot be adjusted. The pin-tooth transmission three-drum dryer can reach a speed of 10-12 rpm, and the speed can be adjusted according to the change of material moisture, and stepless speed change can be achieved. Therefore, compared with the same model and specification dryer, the drying output can be increased by 30%-40%. After three years of use in the dry mortar and slag drying industry, the output has been increased by more than 30-40% compared with the same model and specification dryer.

2. Variable frequency speed regulation of the drum can be realized

Ordinary three-drum dryers use two or four motors to drive the supporting wheels, and the belt and supporting wheels are the main transmission methods, which are difficult to achieve synchronization. The SH type pin-tooth transmission three-drum dryer uses a single motor transmission, gears as the main transmission method, and belts and supporting wheels as auxiliary transmission methods, which solves the problem of asynchrony. At the same time, variable frequency control is adopted, and the drum speed can be adjusted according to the parameter changes of material moisture and drying requirements.

Due to the high transmission efficiency of the pin wheel, the transmission efficiency reaches 96%, which increases the useful power of the motor and reduces power consumption. The friction transmission efficiency of the traditional four motors can only reach 65%, so it saves more than 30% of electricity, especially for materials with high moisture content and large output requirements.

3. Long service life of belts and rollers

The original three-drum dryer uses four rollers and two belts as the transmission method. The dryer is subjected to a large load under full load, and the friction between the belts and rollers is large, and the wear is strong. The SH type pin-tooth transmission three-drum dryer uses gears as the main transmission method, and belts and rollers as auxiliary transmission methods, which effectively extends the service life of belts and rollers.

Material characteristics of pin-tooth transmission three-drum dryer:

SH type pin-tooth transmission three-drum dryer is a simple structure, stable transmission, convenient adjustment, large overlap coefficient, low center distance installation requirements, strong applicability, and the new gear transmission not only fills the gap in the dryer transmission structure, but also makes up for the defects of friction transmission. The whole set of gears is made of 40Gr material, and is subjected to surface high-frequency quenching treatment, with a hardness of 40-50HRC, so as to be durable.

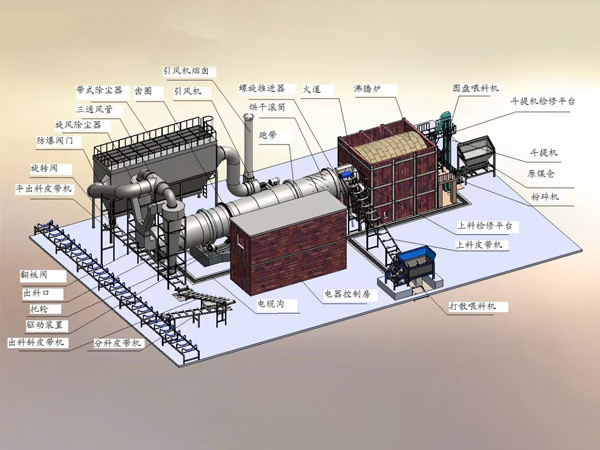

Process flow equipment performance of pin-tooth transmission three-drum dryer:

SH type pin-tooth transmission three-drum dryer is composed of three concentric circles of different diameters embedded in each other as the main body of the dryer. The main body rotates horizontally on the four supporting wheels at both ends through the wheel belts at both ends, and the feeding end of the cylinder is connected to the hot air furnace device. The unloading end is equipped with a dust cover and an automatic unloading device. The dust cover is connected to the dust collector through a pipeline. The dust removal equipment, feeding equipment and conveying equipment can be designed separately according to the user's process conditions and requirements.

The drying process of the SH type pin gear transmission three-drum dryer is realized in this way. The dried material is fed into the inner cylinder of the dryer from the feeding end. The material enters the inner cylinder through the spiral guide plate of the inner cylinder. There are many spiral lifting plates inside the inner cylinder. The material is constantly lifted and moved longitudinally by the lifting plate through the rotation of the cylinder. When the material reaches the left end of the inner cylinder, it falls into the outer cylinder due to its own weight. Through the guide plate, the material is pushed back to the outer cylinder under the action of the rotation of the cylinder. Under the action of the lifting plate of the outer cylinder, the material moves to the right until it reaches the right end of the outer cylinder. When the speed of the dryer changes, the output also changes accordingly. The three concentric cylinders of the dryer body are equipped with different numbers and angles of curved spiral lifting plates, and each cylinder end is equipped with a guide plate. The wet materials to be dried are fed into the feeding end of the inner cylinder through the feeding device and the feeding pipe. The wet materials are quickly pushed to the spiral lifting plates through the spiral guide plates. As the cylinder rotates, the spiral lifting plates in the three cylinders lift the materials while continuously rolling, scattering and moving longitudinally toward the discharge end. At the same time, the hot air flow from the hot air furnace enters the inner cylinder and the outer cylinder successively to exchange intense heat with the materials. Since the metal steel plate conducts heat faster than the material being dried, the steel plate and the lifting plate of the cylinder are heated first, and then the heat is transferred to the material by conduction and radiation. The temperature of the material rises after being heated. When the temperature rises to the temperature at which water evaporates, the water vapor is separated from the material and discharged into the atmosphere after passing through the dust collector with the smoke, thereby achieving the purpose of drying the material.

|

|