-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

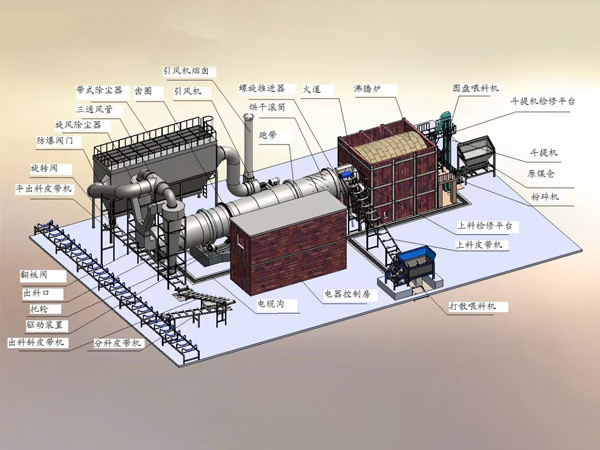

Dry Mortar Drying Production Line

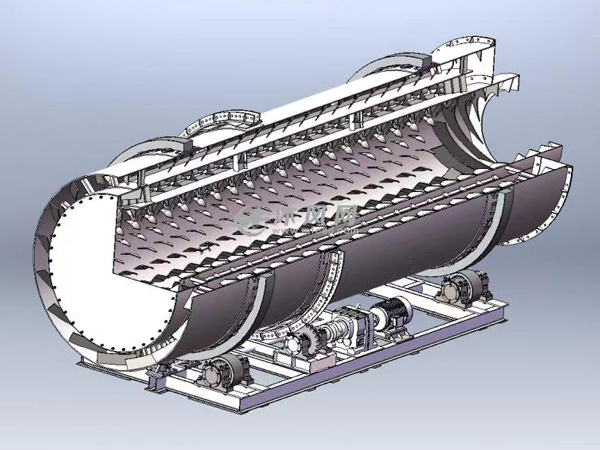

The mortar dryer has a compact structure and small footprint, which is half the footprint of a single-drum dryer with the same output. It is reliable, has low energy consumption, high thermal efficiency, good material drying effect, easy to realize automatic control, and requires fewer operators.

Main uses:

The mortar dryer is mainly used to dry granular materials within a certain humidity range, such as yellow sand used in the dry mortar industry and various specifications of molding sand used in the casting industry. Blast furnace slag used in the building materials cement industry. Small-grained clay, small-grained materials used in the chemical industry that do not undergo chemical changes and are not afraid of high temperature and smoke. According to the requirements of different industries for the final moisture content of the dried material, the moisture content of the dried material can reach below 1-0.5%.

The material entering the dryer should not stick to the drum wall and the poplar plate. The temperature of the gas entering the dryer for heat exchange should not be higher than 750 degrees Celsius. If there is a special requirement for high-temperature drying, the inner drum and the poplar plate at the entrance of the dryer can be made of heat-resistant steel plates.

|

|