-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

Fly Ash Three-Drum Dryer

1. Introduction to fly ash

Fly ash is a volcanic ash-like mixed material formed by high-temperature combustion of coal powder. It is produced by coal-fired power plants. The coal is ground into coal powder below 100 microns, and the preheated air is sprayed into the furnace to form a suspended state after combustion, which produces high-temperature flue gas mixed with a large amount of incombustibles. The fly ash is obtained by collecting it through a dust collector. The chemical composition of fly ash is similar to that of clay, and the main components are silicon dioxide, aluminum oxide, calcium oxide and unburned carbon.

2. Current status of fly ash utilization

my country is a large coal-producing country, with coal as the basic fuel for electricity production. In recent years, my country's energy industry has developed steadily, with an annual growth rate of 7.3% in power generation capacity. The rapid development of the power industry has brought about a sharp increase in fly ash emissions. The total amount of fly ash emitted by coal-fired thermal power plants has increased year by year. In 1995, the fly ash emissions reached 125 million tons, in 2000 it was about 150 million tons, and by 2010 it will reach 200 million tons, which has put tremendous pressure on my country's national economic construction and ecological environment. On the other hand, my country is a country with limited per capita resource reserves. The comprehensive utilization of fly ash, turning waste into treasure and harm into benefit, has become an important technical and economic policy in my country's economic construction. It is an important means to solve the contradiction between environmental pollution and resource shortage in my country's power production, and it is also one of the tasks faced by power production. After development, fly ash has been widely used in various departments such as construction, building materials, and water conservancy.

In the 1970s, the global energy crisis, environmental pollution, and the depletion of mineral resources strongly stimulated the research and development of fly ash utilization. International fly ash conferences were held many times, and the research work became more and more in-depth, and the application has also made great progress. Fly ash has become a new building material and chemical product raw material with rich resources, low price, and benefits and harm elimination in the international market, and it is favored by people. At present, most of the research on fly ash has shifted from theoretical research to applied research, especially the research and development of important resources. The products produced using fly ash are increasing, and the technology is constantly updating. Compared with the past, the comprehensive utilization of fly ash at home and abroad has undergone major changes, mainly manifested in: the guiding ideology of fly ash management has changed from the past simple environmental perspective to comprehensive management and resource utilization; the way of comprehensive utilization of fly ash has developed from the past application in roadbed, backfill, concrete admixture, soil transformation, etc. to the current use in cement raw materials, cement mixed materials, large-scale water conservancy hub projects, pumped concrete, large-volume concrete products, fillers, etc.

3. Fly ash dryer technology

In recent years, my country's cement industry has made major breakthroughs in the comprehensive utilization of resources, and the waste consumed by the cement industry accounts for more than 80% of the total solid waste utilization in the country. The cement industry can use fly ash, slag, coal gangue and other industrial waste residues produced by power consumption, metallurgy, and coal industry by adopting less clinker, more micro powder, and low-cost cement production technology. my country's traditional cement production process uses clinker and mixed materials for mixed grinding. The mill has low output and high energy consumption. Slag and other waste residues are only used as mixed materials, and the amount of addition does not exceed 30%. The process of grinding clinker and slag separately is adopted. The characteristics of slag and other micro-powders that are highly active in a highly fine state and can be used as the main component of cement are used to prepare "blended" cement, and the admixture content reaches 50%-60%, which can greatly reduce the cost of cement production. Cement produced from industrial waste slag can improve the compactness of concrete based on the reasonable matching of various waste slag micro-powder admixtures, form a low-density, high-density, low-defect concrete structure, and greatly improve the service life of concrete. my country produces 1.5 billion to 1.6 billion tons of industrial waste such as slag, and 400 million to 600 million tons of fly ash and coal gangue each year, which are rampant in some areas. Making full use of local cheap fly ash, slag and other waste resources to produce low-cost, high-performance green cement is an important way for cement manufacturing transformation in various regions.

Energy conservation and consumption reduction are important conditions for building a conservation-oriented society and creating a harmonious society, and are also an effective way for cement companies to increase profits. Energy conservation lies in improving efficiency, and the key to improving grinding efficiency lies in reducing the moisture content of raw materials. Since fly ash, slag and other materials have too much moisture when entering the factory, it is not conducive to grinding, resulting in low output of the grinding system, deterioration of the working conditions in the mill such as saturated grinding and paste grinding, and they are dried and dehydrated before entering the mill. Therefore, the production of fly ash dryer provides a good development prospect for the comprehensive utilization of fly ash. The high-yield and energy-saving technology of the new fly ash dryer is a key equipment for the production of fly ash, slag and other micro-powders. In terms of improving cement energy saving, it has made great breakthroughs in design concepts, energy-saving effects and practical applications compared with centrifugal dehydration equipment and old vertical dryers.

Old vertical dryer: The equipment consists of an external combustion furnace, a vertical dryer host and environmental protection equipment. The vertical dryer is built with refractory bricks, and the abdominal cavity has multiple groups of aggregate hoppers and sliding basins. Its working principle is: the material is sent to the upper part of the vertical dryer by the conveying equipment, and descends and sinks through the aggregate hopper and sliding basin by its own gravity. The combustion furnace generates heat energy, which is discharged through the environmental protection equipment after heat exchange through the vertical dryer. Although the angles of the collecting hopper and the sliding material basin slow down the speed of material descent and prolong the heat exchange time of the material, the sliding of the material in the collecting hopper and the sliding material basin is unloading, and the wind tunnel formed is also filtering the material with a large amount of hot air. In addition, the continuous heat dissipation of the cylindrical combustion furnace, the thermal energy utilization rate is only about 50%. The advantages of this equipment are: small footprint and low investment; the disadvantages are: ① high coal consumption, thermal energy utilization rate of about 50%; ② high power consumption, about 4kWh per ton of dry material; ③ poor adaptability, frequent jamming and blocking of materials; ④ strict requirements on heating coal; ⑤ uncontrollable drying quality.

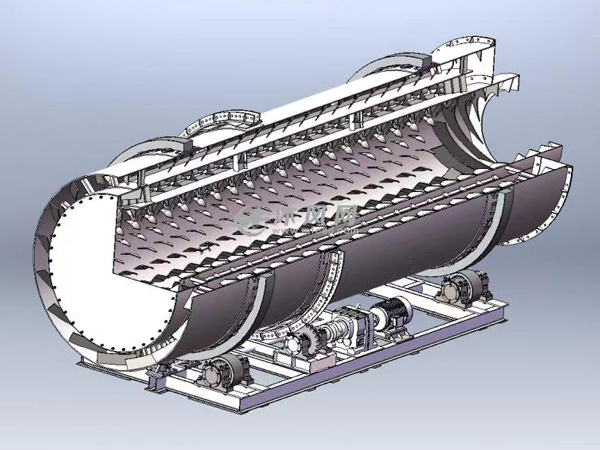

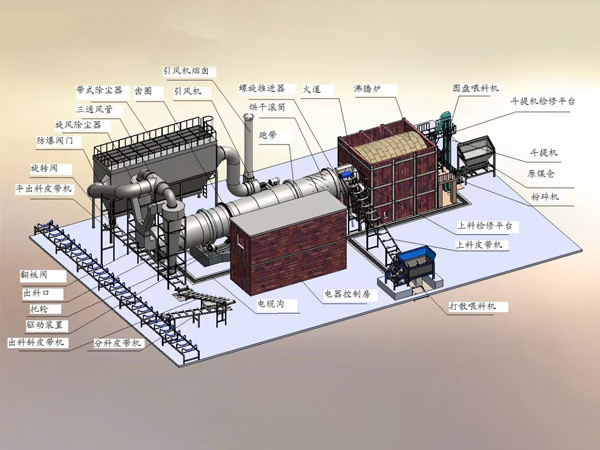

The previous centrifugal dehydration machinery was expensive, low in production capacity, and small in dehydration range. It can usually only reduce water by about 10% at a time, and there is still 15-20% water content. The complete process of the new fly ash dryer consists of three parts: heating system, heat exchange system and ventilation and dust removal system. The heating system adopts hot air furnace technology, which has sufficient heat, good heat transfer effect and simple structure; the heat exchange system is a drying drum, and the material-raising plates in the drum are staggered and arranged in a spiral shape, repeatedly scattering materials, and the heat exchange efficiency is high; the ventilation and dust removal system needs to be equipped with a dust collector. Since the fly ash particles are fine and light in density, they are easily carried away by the air flow under negative pressure after drying, resulting in changes in the fluid medium. In addition, the dust-containing gas has a large amount of moisture, which prevents it from being sucked out by the induced draft system and discharged into the atmosphere, causing resource waste and environmental pollution. The dust is collected uniformly by the dust collector.

The fly ash dryer first sends the wet ash from the conveyor to the horizontal rotary cutter for crushing to prevent the block material from entering the drying drum and affecting the drying effect. The crushed material is then sent to the drying drum. There are many lifting plates in the drum, arranged in a spiral shape. The rotation of the drum drives the lifting plates to continuously throw and scatter the material, and the beating device on the drum wall crushes the material again. The lifted material is fully in contact with the hot air flow introduced by the induced draft system, heat exchange is carried out, the water evaporates, and the drying is completed. It is discharged from the discharge port, and the discharged dusty and wet air is uniformly collected by the dust removal equipment. Fly ash dryer - energy saving, environmental protection.

|

|