-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

Vertical Mill Explosion-Proof Bag Dust Collector

Dust explosion is the phenomenon that dust particles suspended in the air are fully in contact with oxygen in the air and the oxidation reaction is completed instantly under specific conditions. A large amount of heat is released in the reaction, which leads to high temperature and high pressure. Any dust explosion has the following three conditions: ignition source; combustible fine dust; dust suspended in the air and reaching the explosion concentration range.

How to prevent dust explosion with explosion-proof bag filter

1. Characteristics of dust explosion

(1) Dust explosion is more complicated than combustible substances and combustible gases. Generally, combustible dust is suspended in the air to form a dust cloud within the explosion concentration range. Under the action of the ignition source, part of the dust in contact with the ignition source is first ignited and forms a small fireball. Under the action of the heat released by the combustion of this small fireball, the surrounding dust is heated, the temperature rises, and ignition and combustion occurs. In this way, the fireball will expand rapidly to form a dust explosion.

The difficulty and severity of dust explosion are closely related to the physical and chemical properties of dust and the surrounding air conditions. Generally speaking, the greater the combustion heat, the finer the particles, and the more active the dust, the greater the risk of explosion; light suspended combustible materials are more likely to explode; when the oxygen content in the air is high, the dust is easily ignited and the explosion is more violent. Since moisture has the function of preventing explosions, the drier the dust and gas, the greater the risk of explosion.

(2) After a dust explosion occurs, a secondary explosion often occurs. This is because during the primary explosion, a lot of dust is deposited together, and its concentration exceeds the upper limit of the dust explosion concentration value and cannot explode. However, when the shock wave or air wave formed by the primary explosion re-raises the deposited dust, it mixes with the air in the air, and the concentration is within the dust explosion range, a secondary explosion may occur immediately. The disaster caused by the secondary explosion is often much more serious than the primary explosion.

The direct cause of the dust explosion accident in a domestic aluminum product production plant in 1963 was the friction between the exhaust fan impeller and the suction end face, which caused the fire. The shrimp bend and the three-way trousers at the suction inlet of the fan have poor air flow and are prone to dust accumulation. Especially when the machine is shut down, dust is more likely to be retained. Once it is started, the deposited dust is stirred up and quickly reaches the lower explosion limit, causing a dust explosion.

(3) Mechanism of dust explosion When combustible dust burns in the air, it releases energy and produces a large amount of gas. The speed of energy release, that is, the size of the combustion rate, is related to the area of the powder exposed to the air. Therefore, for the powder of the same solid material, the smaller the particle size, the larger the specific surface area, and the faster the combustion spreads. If the particle size of this solid is very fine, it can be suspended. Once there is an ignition source to ignite it, it can release a large amount of energy in a short time. This energy does not have time to dissipate into the surrounding environment, causing the gas in the space to be heated and adiabatically expanded. On the other hand, when the powder burns, a large amount of gas is produced, which will cause the system to form a local high pressure, resulting in explosion and propagation. This is usually called a dust explosion.

(4) The difference between dust explosion and combustion The combustion of large pieces of solid combustibles is to advance inward in nearly parallel layers, such as the combustion of coal. This combustion releases energy relatively slowly. The heat and gas generated can escape quickly. The pile combustion of combustible dust forms open flame combustion under good ventilation conditions, but under poor ventilation conditions. It can form a smoldering fire without smoke or flame.

There are several stages in the combustion of combustible dust: in the first stage, the surface powder is also heated; in the second stage, the surface layer is vaporized and volatiles overflow; in the third stage, the volatiles start gas phase combustion.

The explosion of ultrafine powder is also a relatively complicated process. Since the scale of the dust cloud is generally small, and the flame propagation speed is fast, several hundred meters per second, the fire source ignites in the middle of the dust and can burn the entire dust cloud in less than 0.1s. In this process, if the dust has been burned out, a higher pressure will be generated; if it has not been burned out, a lower pressure will be generated. Whether the combustible particles can be burned out depends on the size of the particles and the depth of combustion.

(5) Classification of combustible dust Powders can be divided into two categories according to their combustibility: one is combustible; the other is non-combustible. The classification methods and standards of combustible powders vary in different countries.

The United States classifies combustible powders as Class II hazardous materials, and at the same time classifies metal powders, carbon-containing dusts, and grain dusts into different groups. The classification method developed by the United States is to classify the powder according to the pressure increase rate when the powder explodes in the standard test device, and divide it into three levels. At present, there is no ready-made standard for the classification of combustible dust in my country.

2. The influence of dust concentration and particles on explosion

(1) Dust concentration Combustible dust explosion also has an upper and lower limit of dust concentration. This value is affected by many factors such as ignition energy, oxygen concentration, powder particle size, powder type, moisture, etc. Using a simplified formula, the explosion concentration can be estimated. Generally speaking, the lower limit of dust explosion is 20-60g/m3, and the upper limit is between 2-6kg/m3. The upper limit is affected by many factors, and its value is not as easy to determine as the lower limit, and it is usually not easy to reach the upper limit concentration. Therefore, the lower limit value is more important and more useful.

In a physical sense, the upper and lower limits of dust concentration reflect the influence of the distance between particles on the propagation of particle combustion flames. If the distance between particles is such that the combustion flame cannot extend to adjacent particles, then the combustion cannot continue (propagate), and the explosion will not occur; at this time, the dust concentration is lower than the lower limit of the explosion. If the distance between particles is too small, the oxygen between particles is insufficient to provide sufficient combustion conditions, and an explosion cannot be formed. At this time, the particle concentration is higher than the upper limit.

(2) When the particle size of the powder is larger than 400um, the dust cloud formed is no longer explosive. However, for ultrafine powders, when the particle size is below 10um, it is more dangerous. It should be noted that sometimes even if the average particle size of the powder is greater than 400um, it often contains finer powder, and this small part of the powder is also explosive.

Although the regularity of the effect of the particle size of the powder on the explosion performance is not strong, the smaller the size of the powder, the larger its specific surface area, the faster it burns, and the pressure rise rate increases linearly. Under certain conditions, the pressure does not change much, because it depends on the total energy released during combustion, and has no obvious relationship with the speed of energy release.

3. Technical measures for dust explosion

The combustion reaction requires combustible substances and oxygen, and an ignition source with a certain energy. For dust explosion, there should be three elements: ignition source; combustible fine dust; dust suspended in the air, forming a dust cloud within the explosion concentration range. Only when these three elements exist at the same time will an explosion occur. Therefore, as long as one of the conditions is eliminated, the explosion can be prevented. The following technical measures are often used in bag dust collectors.

(1) Explosion-proof structural design measures In the special design of the main structure, in order to prevent the accumulation of combustible dust in the internal components of the dust collector, all beams, partitions, etc. should be equipped with dust-proof plates, and the slope of the dust-proof plates should be less than 70 degrees. The sliding angle of the ash hopper is greater than 70 degrees. In order to prevent dust accumulation due to the small angle between the two hopper walls, the two adjacent side plates should be welded with sliding plates to eliminate dust deposition. Considering that the ash hopper will condense and block when the dust humidity is high due to abnormal operation, when designing the ash hopper, steam pipe insulation or tubular electric heaters are added to the ash hopper wall for high-temperature dust collectors. In order to prevent the ash hopper from accumulating, each ash hopper is also required to be equipped with a bin arm vibrator or air cannon.

A dust collector has at least 2 to 3 ash hoppers, and at most 5 to 8 ash hoppers. When in use, uneven air volume will cause deflection, uneven coal powder volume in each ash hopper, and large ash volume behind H.

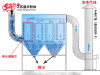

To solve the problem of uneven air volume, the following measures can be taken in the structure: ① Add a wind baffle on the inclined baffle of the air duct, as shown in Figure 5-168. The size of the baffle needs to be determined according to the principle of equal air volume and equal wind pressure; ② Considering the actual changes on site, an adjustable valve is used between the lifting valve stem and the valve plate to make the outlet height h a variable value for further correction; ③ An air volume regulating valve is installed on the air inlet branch pipe to adjust the air volume of each chamber after the equipment is running. The difference in air volume of each chamber is controlled within 5%.

(2) Anti-static filter bags are used inside the dust collector. Since high-concentration dust rubs against each other during the flow process, dust and filter cloth also rub against each other, which can generate static electricity. The accumulation of static electricity will generate sparks and cause combustion. For pulse cleaning, the filter bag uses polyester needle felt. To eliminate the static electricity generated by polyester needle felt, conductive metal wire or carbon fiber is spun into the filter bag fabric. When installing the filter bag, the filter bag is connected to the porous plate through the steel frame and connected to the workshop grounding network through the shell. For the filter bag with back-blowing cleaning, a variety of anti-static products such as MP922 have been developed. The use effect is very good.

(3) Setting holes (valves) To limit the explosion to the inside of the bag filter and not to expand to other areas, it is important to set holes and necessary fire extinguishing equipment. The purpose of setting holes is not to prevent explosions, but to limit the scope of explosions and reduce the number of explosions. Most dust collectors that handle explosive dust are operated under the condition of setting holes. Because of this, the design of the holes should ensure that they can play a practical role in the event of an explosion accident; the maintenance and management of the holes should be strengthened at ordinary times.

The rupture plate type safety hole is made of ordinary thin metal plate. Because the bag dust collector box cannot withstand great pressure, the strength of the rupture plate should be designed so that the plate will be destroyed at a lower pressure. Sometimes, due to the long-term pressure on the box, the aluminum plate will be fatigued and deformed, resulting in rupture. Even if this is normal, it is not allowed to replace the high-strength thick plate.

The spring gate hole adjusts the opening pressure by increasing or decreasing the spring tension. In order to ensure that the gate hole can effectively play a role in an accident, it should be tested regularly.

The area of the hole should be determined according to the relationship between the maximum pressure during dust explosion, the speed of pressure increase, and the compressive strength of the box, but there is no exact data at present. The size of the hole area should be determined according to the form and structure of the bag dust collector. We believe that the ratio of the hole to the volume of the dust collector for small and medium-sized dust collectors is 1/10 to 1/30, and the ratio for large and medium-sized dust collectors is 1/30 to 1/60. When encountering difficulties, refer to the actual determination of the reserved explosion-proof holes of other devices.

① Explosion-proof plate Explosion-proof plate is an emergency pressure relief device driven by pressure difference and non-automatically closed. It is mainly used for pipelines or dust removal equipment to prevent them from being damaged by overpressure or vacuum. Compared with valves, bursting discs have the advantages of large discharge area, sensitive action, high precision, corrosion resistance and not easy to clog. Bursting discs can be used alone or in combination.

The explosion-proof plate device consists of a bursting disc and a clamp. The clamp is made of materials such as Q235, 16Mn or OCr13. Its function is to clamp and protect the explosion-proof plate to ensure the stability of the bursting pressure. The explosion-proof plate is made of materials such as aluminum, nickel, stainless steel or graphite, and has different shapes: the concave surface of the arched explosion-proof plate faces the pressure side, and tensile or shear failure occurs during explosion; the convex surface of the reverse arched explosion-proof plate faces the pressure side, and it is cut by the blade or torn along the seam due to sudden flipping due to instability during explosion; the plane-shaped explosion-proof plate also undergoes tensile or shear failure during explosion.

The pressure resistance of the explosion-proof plate selected for the dust collector should be based on the working pressure of the dust collector. Because the pressure resistance requirement of the dust collector body is 8000~18000Pa, check the data according to the set pressure resistance requirements to determine the rupture pressure of the explosion relief valve membrane.

② Explosion-proof valve design There are two main types of explosion-proof valve designs: one is the explosion-proof plate; the other is the heavy hammer explosion-proof valve. The former needs to replace a new plate after rupture, and the production needs to be interrupted. When encountering high negative pressure, it is easy to break and difficult to keep warm. The latter is more advanced than the former. It relies on heavy hammer pressure in the closed state and has poor tightness. Both of the above methods are not suitable for high-pressure pulse cleaning. In order to solve the problem of tightness, an explosion-proof lock can be designed on the heavy hammer explosion valve. Its characteristics are: when closed, the door is mainly locked through this lock, and it can be automatically opened and released in the event of an explosion, and its release force can be adjusted by a spring. In order to balance the force on the door, generally 4 to 6 locks are required according to the door area. In order to make the explosion-proof door airtight and airtight, it can be designed into a double structure of explosion-proof plate and lock.

(4) Detection and fire-fighting measures To prevent accidents before they happen, necessary fire-fighting measures can be taken in the dust removal system.

① Fire-fighting facilities. They mainly include water, CO2 and inert fire extinguishing agents. For cement plants, they mainly use argon and CO2, while steel plants can use nitrogen.

② Temperature detection. In order to eliminate the temperature changes of the dust collector and control the ignition point, several thermometers are generally installed at the entrance of the dust collector and on the ash hopper.

③ CO detection. For large dust removal equipment, due to its large size, the installation of thermometers is very limited. Sometimes, combustion occurs at a distance from the thermometer measurement point and is difficult to reflect on the thermometer. A CO detection device can be installed at the outlet of the dust collector to help with detection. As long as combustion occurs anywhere in the dust collector, the CO in the flue gas will increase. At this time, the alarm of increased CO concentration is linked to the dust removal system control to stop the operation of the system dust collector in time.

(5) Equipment grounding measures Explosion-proof dust collectors are often arranged outdoors due to operational needs. Even if it is arranged outdoors on a tall steel structure, according to the grounding requirements of the equipment, grounding and lightning protection of the equipment has become an indispensable measure, but the dust collector is generally not equipped with a lightning rod.

A conductor with good conductivity is added between all the connection flanges of the dust collector. The conductor can be made into a card type. It can also be made into a line type. Line type conductors are shown in the figure. Card type conductors are shown in the figure. No matter which form of conductor is used, the connection must be firm and buried on the surface, with a certain corrosion resistance. Otherwise, it will affect the grounding and lightning protection effect of the equipment.

(6) Explosion-proof of supporting components It is essential to select explosion-proof components in the explosion-proof measures of the dust collector. Explosion-proof dust collectors are taboo to allow dust in the operating conditions to enter the electrical load and induce explosion hazards. When the dust collector is running, the electrical load and components are inevitably electric shock-incinerated when the current is transmitted and contacted, and even when they are turned on. It is also easy for discharge sparks to induce explosions of dust source gases exceeding a relatively high concentration. All electrical load components must use explosion-proof components to eliminate explosion-inducing factors. Ensure the correct operation and operation of the equipment. For example, the pulse valve and solenoid valve used for the lift valve of the pulse dust collector should all be explosion-proof products.

(7) Measures to prevent sparks from entering the bag dust collector In the bag dust collector that processes waste gas from wood chip boilers, rice husk boilers, aluminum regeneration furnaces and smelting furnaces, the burned dust in the furnace may enter the box with the airflow of the duct, causing the dust accumulated on the filter cloth to ignite and cause an accident.

To prevent sparks from entering the bag dust collector, the following measures should be taken:

① Set up a pre-dust collector and a cooling duct. The figure shows a cyclone dust collector or an inert dust collector as a pre-dust collector to capture coarse dust and sparks. Using this method, sparks that are too fine are not easy to capture. In most cases, the fine dust can be burned before entering the dust collector. Set up a cooling duct after the pre-dust collector and control the flow rate in the duct to make it as low as possible. This is a relatively reliable technical measure that allows the gas to have sufficient residence time in the duct.

② Lingque spray tower. A gas cooling method that directly sprays water in advance. In order to ensure the fire prevention of dust-containing gas in the bag filter, the cooling water supply is controlled. Most of the burning dust can be cooled once it comes into contact with fine water droplets, but water droplets are easy to gasify. In order to cool the burning dust that has not yet come into contact with water droplets, necessary space and residence time should be provided.

In special cases, spray towers, cooling pipes and pre-dust collectors are used in combination to prevent sparks from mixing in.

③ Spark capture device is shown in the figure. Installing a spark capture device on the pipeline is a simple and feasible method. In addition, when the spark passes through the collector, it can send an electrical signal to alarm. At the same time, stop the operation or change the gas circuit, etc.

The design requirements of the spark catcher are as follows:

a. When the spark catcher is used to capture spark particles in high-temperature flue gas, the main material of the equipment is generally 15Mo3 or 16Mo, and Q235 is used for beams, columns, platform ladders, etc. When the spark catcher is used as a flue gas pre-separator, except for the rotating blades that generally use 15Mn, other materials can be Q235;

b. The inlet and outlet speeds of the equipment are generally between 18 and 25m/s;

c. Consider the dust separation effect. The blades should have certain wear-resistant measures and appropriate rotation angles;

d. The equipment structure design should take into account the deformation of the equipment caused by high temperature.

(8) Control the inlet dust concentration and add non-combustible powder. During the operation of the bag dust collector, its internal concentration distribution will inevitably make a certain part within the explosion limit, avoiding the concentration between the upper and lower limits of the dust explosion in the pipeline. For example, in dust collection work such as pneumatic conveying and crushing and classification, it is necessary to pay attention to the design so that it can operate at a high concentration exceeding the upper limit; in the case of local collection, the dust concentration in the pipeline should be kept at a low concentration below the lower limit.

An example of using the dilution method to prevent fire. When collecting explosive dust, the dust is diluted with air due to the installation of a dust hood, and the concentration in the pipeline is far below the lower explosion limit. Non-combustible powders such as clay and bentonite are continuously supplied from the middle of the system to the pipeline to dilute the explosive dust inside the dust collector to prevent the risk of explosion and fire.