-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

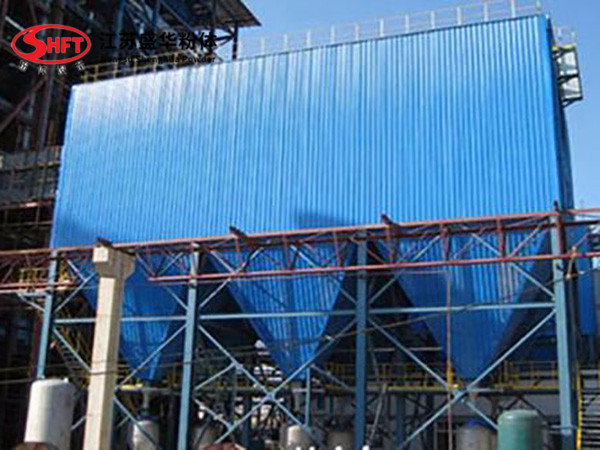

Large Bag Dust Collector

Bag dust collector is a kind of filtering and dust removal equipment with a wide range of uses. It is mainly used to isolate solid impurities and gases to achieve the effect of filtering and improving air quality. This equipment is used in various chemical companies and is also common in civilian homes. The reason why it is called a bag is that the filter medium of this dust removal equipment is generally made of fabric. The performance of the dust collector is expressed by the amount of gas that can be processed, the resistance loss when the gas passes through the dust collector, and the dust removal efficiency. At the same time, the price, operation and maintenance costs, service life and difficulty of operation and management of the dust collector are also important factors to consider its performance. Dust collector is a commonly used facility in boilers and industrial production.

Working principle

The dust-containing gas enters the filter chamber from the lower open flange, and the coarser particles fall directly into the ash bin. The dust-containing gas is filtered by the filter bag, and the dust is retained on the bag surface. The clean gas passes through the bag mouth to the clean air chamber and is discharged into the atmosphere by the fan. When the dust on the surface of the filter bag continues to increase, the program controller starts to work, opens the pulse valve one by one, and allows compressed air to blow and clean the filter bag through the nozzle, causing the filter bag to expand suddenly. Under the action of the reverse airflow, the dust on the bag surface quickly detaches from the filter bag and falls into the ash bin, and the dust is discharged by the ash discharge valve.

Purpose

A dust hood is set at each dust-emitting place, and the dust-containing gas is transported to the dust removal device through the pipeline air path. After gas-solid separation, the dust is collected in the dust removal device, and the clean gas is introduced into the main pipe or directly discharged into the atmosphere. The whole set of equipment is the dust removal system, and the dust collector is an important component of the system. From the perspective of ventilation and dust removal, dust is all small solid particles that can exist in the air in a floating state for a long time. It is a dispersed system called aerosol, in which air is the dispersion medium and solid particles are the dispersed phase. The dust collector is a device that separates such small solid particles from the aerosol.

Temperature material classification

1. Normal temperature bag: Normal temperature bag is mainly made of polyester, polypropylene, acrylic and other fibers through non-woven and textile processes. It has excellent properties such as good air permeability, smooth surface, good dimensional stability, and easy dust removal [2]. It is mainly used in dust removal in general industrial enterprises with dust pollution and normal temperature flue gas treatment.

2. Medium temperature bag: With the increasing attention paid by the country to environmental protection, especially the rapid development of bag dust removal technology in recent years, China has begun to use imported synthetic fibers to develop high-performance filter materials that can adapt to relatively harsh working conditions and have a long service life. At present, the more common medium temperature filter materials include aramid fiber and PPS series fiber, which are processed by impregnation, waterproof, oil-proof and corrosion-resistant processes to achieve ideal results.

3. High temperature bag: High temperature bag is mainly made of P84, expanded glass fiber, ultra-fine glass fiber and other high temperature resistant fibers through textile and non-woven processes. It has the characteristics of good thermal stability, high filtration efficiency and long service life. Mainly used in dust collectors under various high-temperature flue gas conditions; DWD high-temperature bags are used for parts with harsh working conditions, while polyester bags are used for ordinary dust collection parts.

Maintenance of bag dust collector

1. When the bag dust collector is under maintenance, first cut off the power supply, the operator carries the key to the operating panel, and hangs a sign on the operating panel that says "under maintenance, strictly prohibited from operation".

2. Transmission devices such as couplings, transmission belts, and transmission wheels of vibration devices, star-shaped dischargers, exhaust fans, etc. must be equipped with protective covers to prevent bolts from loosening and belts and chains from flying out and injuring people when they break.

3. During daily inspections or operation, when temporarily handling faults, operators must prevent clothing from being entangled in the transmission device. When entering the ash hopper to clean the ash or entering the filter bag room to hang bags, wear labor protection equipment to prevent dust from blinding the eyes or burning the skin.

4. For bag dust collectors that handle flammable and explosive dust gases, such as bag dust collectors used in coal mills, dust should be accumulated in the dust collectors frequently to prevent combustion or explosion, and fire should be prevented from entering. It is strictly forbidden to use electric welding or gas welding to repair pipes or shells during operation.

5. For positive pressure glass fiber bag dust collectors that handle high-temperature gases, measures to prevent heatstroke should be taken when entering the gas distribution room to hang filter bags in summer.

6. When entering the dust collector that handles harmful and toxic gases for maintenance, it is necessary to prevent possible hypoxia and harmful gas poisoning accidents, and the gas in the system can be replaced with air.

7. After each maintenance, carefully check whether there are tools or other debris dropped into the equipment. Check whether the protective covers are properly installed and do not act rashly.

8. When the equipment of the dust collection system is started or stopped, contact other positions and agree to start or stop according to the start and stop sequence specified in the operating procedures.