-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

Bag Filter

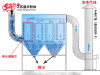

Bag filter, also known as filter filter, is a high-efficiency dry dust removal equipment. Its main components include upper box (clean air chamber), middle box (dust air chamber), ash hopper, pulse cleaning system, filter bag, filter bag frame, air inlet and outlet, differential pressure gauge, inspection manhole, ash unloading device and PLC controller, etc.

The working principle of bag filter is based on the filtering effect of fiber fabric. When the dust-laden gas enters the dust collector, large particles and heavy dust settle due to gravity and fall into the ash hopper. When the gas containing finer dust passes through the filter bag, the dust is retained, so that the gas is purified. The cleaned gas is discharged from the air outlet.

As the dust accumulates on the surface of the filter bag, the resistance of the dust collector gradually increases. When the resistance value reaches a certain level, the pulse controller issues a command to start the injection valve. The compressed air in the air bag is ejected at high speed through the injection pipe, inducing the surrounding air several times the amount of the injected air to enter the bag, and eject it quickly from the inside to the outside, blowing the dust on the outer surface of the bag down into the dust collecting chamber, and then discharged from the dust hopper. This process is the dust cleaning process of the bag dust collector, which helps to keep the dust collector in a continuous and efficient working state.

Bag dust collectors are suitable for capturing fine, dry, non-fibrous dust. They are widely used in manufacturing, coal industry, cement and building materials industry, chemical and pharmaceutical industry, food processing industry, flue gas treatment and other fields. They are important equipment for maintaining air quality, protecting the environment and ensuring workplace safety.