-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

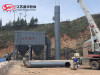

Unpowered Powder Removal Machine

This equipment is widely used in the de-powdering of foundry sand, oil well backfill pressure sand, glass quartz sand, sand and gravel plants and other silt-containing sand.

In order to solve the problem of powder content in various sands, people first use water washing to remove stone powder in sand. In this way, it is required that there are abundant water resources around the sand making. However, wet water washing will not only wash away some qualified sand particles, but also cause secondary pollution to the environment. Therefore, the wind separation sand and gravel system has become a development trend. The birth of the sand and gravel de-powdering machine has solved the needs of this market and protected the environment at the same time.

After sorting by the de-powdering machine, the stone powder is collected by the stone powder special bag dust collector at the back. Features: high sand sorting efficiency, high stone powder control accuracy, finished sand is greater than any value in the range of 0.174 (100 mesh), 0.105mm (150 mesh), 0, 075 (200 mesh).

2. Working principle:

The new sand and gravel separation and powder removal process using a non-powered sand and gravel de-powdering machine and a special dust collector for stone powder is adopted. This scheme is a new type of sand and gravel separation process. The non-powered de-powdering machine is responsible for the coarse and fine separation of materials. The fineness of the separation can be easily achieved by the air volume regulating valve, flow regulating plate, slide angle, etc. The separated coarse powder, that is, sand and gravel, is sent to the yard for storage by a belt conveyor; and the separated stone powder enters the bag dust collector for stone powder with the air flow, and enters the sedimentation chamber set inside. The coarse particles in the air flow are collected by gravity sedimentation and fall into the ash hopper, while the fine particles are collected by the bag dust collector with the air flow and discharged into the atmosphere, and fully meet the national emission standard of 30mg/Nm3; the collected stone powder is sent to the next process by the screw conveyor set at the bottom of the dust collector ash hopper.

3. Structural features:

The system's powder removal machine has no rotating parts, and all the parts in contact with the material are made of imported wear-resistant steel plates, which has little wear on the equipment and is easy to maintain. Secondly, the system has low power consumption, and the unit product power consumption is about 30% lower than the traditional sorting process. In addition, the process layout is simple, and no foundation is required for installation, which saves equipment installation costs.

4. Installation and trial operation requirements

1. Equipment installation

(1) Foundation layout: Baseline layout is carried out according to the process layout and equipment size.

(2) Fixed foundation: The indoor floor surface is flat, the elevation error is not more than 2mm, and the concrete support surface must be no less than 160mm.

(3) Dust collector installation: First, install the lower box body on the embedded steel plate with legs according to the process layout and add a pad to adjust the level, then weld it to the embedded steel plate, and connect and fix the screw conveyor to the lower box body. Then install the upper box body shell, align it with the lower box body, and weld it firmly. No air leakage is allowed during operation.

(4) Fan installation: Before installation, carefully check whether there is any deformation, damage or looseness during the shipping process. Only when there is no problem can the installation be carried out. Fix the shock absorber under the support and ensure that each shock absorber can bear the force.

(5) Installation of the de-powdering machine: Determine the installation height and orientation of the de-powdering machine according to the height and position of the discharge belt conveyor, and fix it with channel steel support and weld it firmly.

2. Pipeline connection: Connect and weld the pipelines between the de-powdering machine and the dust collector, and between the dust collector and the fan.

3. Trial operation

After the installation inspection is qualified, the trial operation can be carried out. The main contents of the trial operation are as follows:

(1) Check the fan and screw conveyor to see if they are flexible and there is no jamming.

(2) The rotation direction of the fan must be consistent with the arrow direction marked on the fan object, and the rotation direction of the screw conveyor must be consistent with the discharge direction, not the opposite, and whether the injection system works normally.

(3) After the equipment is installed, add an appropriate amount of lubricating oil to each lubrication point, and then conduct a trial run for 4-8 hours (high speed) to check the oil supply of each bearing. The equipment can be put into production only after the trial run is fully qualified.

Feeding can only be carried out when all system equipment is operating normally. When stopping, stop feeding first, and then stop the motor and fan after a few minutes.

V. Operation, maintenance and inspection

(1) Lubricating oil should be added to each bearing regularly to ensure that each lubrication point is fully lubricated and all lubricants of each bearing are clean. If there is a rustling sound in the bearing, it is caused by dirt and abnormal lubrication. Repair and remove impurities in time.

(2) The temperature of each bearing shall not exceed 60℃.

(3) Always pay attention to the balance of the fan. If abnormal vibration is found, stop the machine in time to check and eliminate it.

(4) The air duct should be cleaned regularly, and rainwater should be prevented from entering each pipe to avoid dust agglomeration.

(5) Check whether the bag is sticky or damaged. If so, replace it in time.

(6) Maintenance

Maintenance of equipment: After the machine is shut down, the maintenance door should be opened for maintenance after the temperature inside the machine has dropped and the dust has settled. During maintenance, a "under maintenance" sign should be hung at the electrical switch control to avoid accidental start of the machine and injury to people.

After the maintenance is completed, the original sign holder should remove the sign to indicate that the maintenance is completed before the machine can be started.

VI. Product fineness adjustment

If the stone powder content in the sand and gravel coming out of the de-dusting machine exceeds the standard, the de-dusting machine damper can be opened wide. If it still cannot be adjusted to the required standard, the damper of the fan can be opened wide until the fineness meets the requirements. If the finished product is too coarse, the adjustment method is the opposite.

IX. Appendix [GB/T14685-Construction Sand] Standard

GB/T14685-Construction Sand

1. Scope: This standard specifies the terms and definitions, classification and specifications, technical requirements, test methods, inspection rules, standards, storage and transportation of construction sand.

2. Normative references

The following documents are indispensable for the application of this document. For all references with dates, only the versions with the dates are applicable to this document. For all references without dates, the latest versions (including all amendments) are applicable to this document.

GB 175 General Portland Cement

GB/T 601 Preparation of Standard Titration Test Solution for Chemical Reagents

GB/T 602 Preparation of Titration Test Solution for Impurities in Chemical Reagents

GB/T 2419 Test Method for Fluidity of Cement Mortar

GB/T 6003.1 Metal Wire Mesh Test Sieve (equiv ISO 3310-1:1990)

GB/T 6003.2 Metal Perforated Plate Test Sieve (equiv ISO 3310-2:1990)

GB 6566 Limits of Radioactive Nuclides in Building Materials

GB/T 17671 Test Method for Strength of Cement Mortar (ISO Method) (idt ISO 679:1989)

3. Terms and Definitions: The following terms and definitions apply to this standard

3.1 Natural sand

Naturally generated, artificially mined and sieved rock with a particle size of less than 4.75 mm, including river sand, lake sand, mountain sand, desalinated sea sand, but excluding soft, weathered rock particles.

3.2 Manufactured sand

Rock, mine tailings or industrial waste particles with a particle size of less than 4.75 mm, made by mechanical crushing and screening after soil removal, but excluding soft and weathered particles, commonly known as artificial sand.

3.3 Clay content

The content of particles with a particle size of less than 4.75 μm in natural sand.

3.4 Fine content

The content of particles with a particle size of less than 4.75 μm in machine-made sand.

3.5 Clay lumps and friable particles content

The content of particles with an original particle size greater than 1.18 mm and less than 600 μm after water immersion and hand kneading in sand.

3.6 Fineness module

An indicator to measure the coarseness of sand.

3.7 Soundness

The ability of sand to resist rupture under the action of natural weathering and other external physical and chemical factors.

3.8 Light material material lighter than 2000 kg/m3

Material with an apparent density of less than 2000 kg/m3 in sand.

3.9 Alkali-aggregate reaction

Refers to the expansion reaction of cement, admixtures and other concrete components, alkali in the environment and deactivated minerals in aggregates that slowly occurs in a humid environment and causes concrete cracking and destruction.

3.10 Methylene blue (MB) value methylene blue value

It is used to determine the adsorption performance index of particles with a particle size of less than 4.75 μm in machine-made sand.

4. Classification and specifications

4.1 Classification: Sand is divided into natural sand and machine-made sand according to its source.

4.2 Specifications: Sand is divided into three specifications of coarse, medium and fine according to its fineness modulus, and its fineness modulus is:

--Coarse: 3.7~3.1;--Medium: 3.0~2.3;--Fine: 2.2~1.6

4.3 Category: Sand is divided into Class I, Class II and Class III according to technical requirements.

5. General requirements

5.1 The harmful substances in the machine-made sand used for the production of mine tailings and industrial waste residues shall comply with the provisions of 6.3 and comply with relevant environmental protection standards and specifications of my country, and shall not have harmful effects on human body, organisms, environment and concrete and mortar performance.

5.2 The radioactivity of sand shall comply with the provisions of GB 6556.

6. Technical requirements

6.1 Particle grading: The particle grading of sand shall comply with the provisions of Table 1; the grading category of sand shall comply with the provisions of Table 2. For mortar sand, the cumulative sieve residue of 4.75mm sieve hole shall be 0. The actual particle grading of sand can be slightly exceeded except for 4.75mm and 600μm sieves, but the total of the cumulative sieve residue excess values of each level shall not exceed 5%.

Appendix A Particle grading

Appendix B Grading category

6.2 Mud content, stone powder content and mud block content of sand

6.2.1 The mud content and mud block content of natural sand shall comply with the provisions of Table 3.

Appendix C Mud content and mud block content

6.2.2 When the MB value of machine-made sand is ≤1.4 or the rapid test is qualified, the stone powder content and mud block content shall comply with the provisions of Table 4; when the MB value of machine-made sand is greater than 1.4 or the rapid test is unqualified, the stone powder content and mud block content shall comply with the provisions of Table 5.

Appendix D Stone powder content and mud block content (MB value ≤1.4 or rapid test is qualified)

Appendix E Stone powder content and mud block content (MB value >1.4 or rapid test is unqualified)

6.3 Harmful substances: If the sand contains mica, light substances, organic matter, carbide or sulfate, chloride, shell, its limit shall comply with the provisions of Table 6.

Appendix F Harmful substance limit

6.4 Robustness

6.4.1 The mass loss of sand shall comply with the provisions of Table 7 when the sodium sulfate solution method is used for testing

Appendix G Robustness index

6.4.2 In addition to meeting the requirements in 6.4.1, the crushing index of machine-made sand shall also meet the requirements of Table 8.

Appendix H Crushing Index

6.5 Apparent density, loose bulk density, void ratio

The apparent density and loose bulk density of sand shall comply with the following provisions:

--Apparent density shall not be less than 2500 kg/m3;

--Loose bulk density shall not be less than 1400 kg/m3;

--Void ratio shall not be less than 44%.

6.6 Alkali-aggregate reaction: After the alkali-aggregate reaction test, the specimen shall be free of cracks, brittle cracks, colloid overflow, etc., and the expansion rate shall be less than 0.10% at the specified test age.

6.7 Moisture content and saturated surface dry water absorption

When the user requires, the actual measured value shall be reported.