-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

Separator

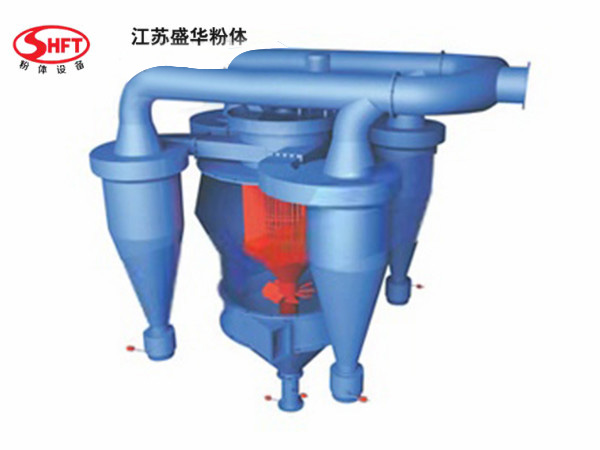

A new type of grading equipment has been developed to overcome the defects of centrifugal and cyclone separators, such as uneven material spreading and uneven grading flow field. The widely used O-Sepa separator is considered to be a typical representative of the third generation of high-efficiency grading equipment.

Working principle:

The material enters from the feed pipe and is scattered into the rising airflow through the dispersion plate. Under the action of gravity, the grinding medium fragments in the material overcome the resistance of the rising airflow and fall down, and are discharged from the slag discharge port. The airflow carrying the powder rises to the grading part and enters the rotor through the guide vane for grading. The guide vane can make the airflow and powder particles produce a rotary motion for pre-grading, and capture the coarse particles thrown out by the rotor, and can also make the airflow speed evenly distributed over the height of the entire rotor. The coarse particles captured by the guide vane fall onto the coarse powder cone and are discharged from the coarse powder outlet, while the fine particles and the airflow pass through the rotor blades into the middle of the rotor and are sent to the collection device from the fine powder outlet.

Product features:

1. The materials are dispersed outside the classification area. Due to the functions of the dispersion plate, the intermediate connecting air duct and the guide vane, it has both static inertial classification and dynamic classification functions, and the material dispersion is high and evenly distributed.

2. The classification area of the high-efficiency separator is narrow and long, the air flow field is balanced and stable, the classification performance is good, and the classification efficiency is high.

3. The high-efficiency separator has a large processing capacity, and the volume can be made smaller than other separators at the same processing capacity.