-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

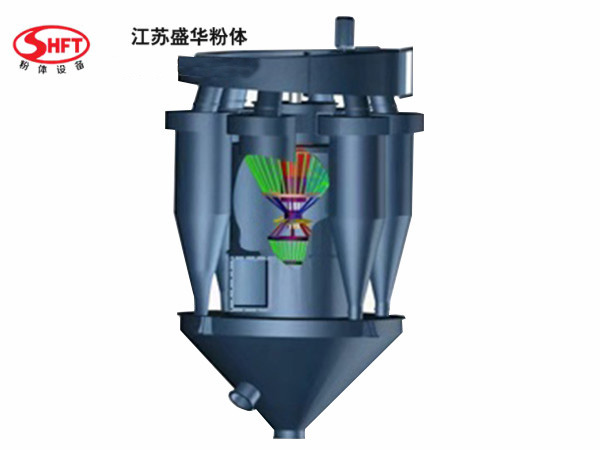

Old Style Rotor Powder Separator

The double rotor separator is a new type of powder selection equipment developed by combining foreign powder technology and applying the flat vortex theory to the cyclone separator. It has been proved that the powder selection efficiency can reach 85-90%, the open flow increase right is 60-80%, the finished product particle size distribution is concentrated, and the fineness adjustment is convenient and flexible, and the performance is stable and reliable.

Main features:

The finished product particle size distribution is concentrated, the particle grading is more reasonable, and the product quality is significantly improved.

Easy to operate, and the fineness is very easy to adjust.

Energy saving and consumption reduction, the system unit power consumption is about 30% lower than that of traditional ring flow powder.

It can increase the open flow right by 60-80%, and the powder selection efficiency can reach 85-90%.

The anti-condensation effect is reliable and can adapt to various climate environments.

It adopts dust-proof and vibration-reducing fans, equipped with vibration-reducing machine bases, which can be directly supported by steel frames, and is particularly convenient to install.

The system investment is low and the operation and maintenance are convenient.