-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

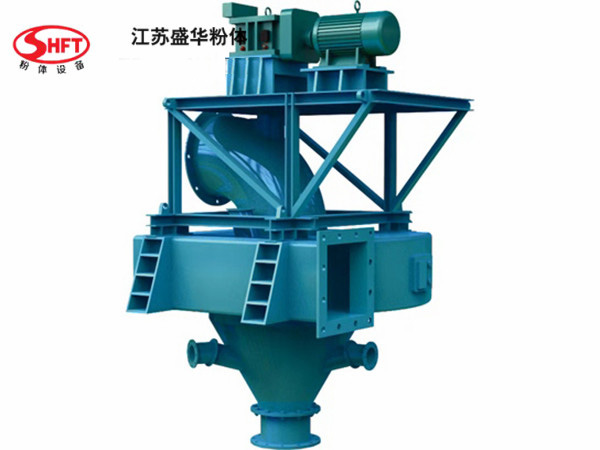

O-SEPA Powder Separator

Product advantages:

O-SEPA vortex separator is a fourth-generation high-efficiency separator that uses the principle of horizontal vortex for classification. It is widely used in the classification of cement industry and powdered materials or other industrial equivalent materials. It has the advantages of high yield and low consumption, large processing capacity, simple operation and maintenance, etc.

O-SEPAseparator adopts vortex field optimized by finite element analysis, volute design, and more reasonable selection of wind guide blade parameters. The powder selection vortex field is uniform, stable and powerful, with low flow resistance, low noise, and high powder selection efficiency, which can effectively reduce the power of dust collecting fans.

O-SEPAseparator adopts a rotor blade design that has won a national patent. The powder selection area extends to the inside of the rotor cascade. The airflow into the cascade channel does not accelerate and the wake loss is small. The rotor cascade has low resistance to airflow and low power consumption. Numerous user feedback shows that it can effectively save energy.

O-SEPAseparator rotor is equipped with a vortex breaker. The airflow in the rotor only rises but does not rotate relative to the rotor. The driving force on the rotor is reduced due to the reduced momentum after the airflow enters the rotor, which saves driving power and reduces wear.

Working principle: The separator outlet bend receives the air inlet of the dust collector. Due to the exhaust effect of the dust collector fan, the air is sucked into the powder selection vortex shell through the separator primary and secondary air ports. Under the guidance of the guide vane, the rotation of the rotor and the fixed buffer plate, a stable annular horizontal vortex powder selection area is formed between the guide vane and the rotor. The ground material is fed from the separator feed port and evenly scattered around by the rotating scattering disk. Due to the blocking effect of the material retaining ring, the material is scattered in the powder selection area between the guide vane and the rotor in a dispersed state. The dust particles moving in the powder selection vortex will be affected by gravity, wind force and rotating centrifugal force at the same time. The fine and light particles are sucked into the rotor with the air flow and collected by the dust collector through the air outlet to become the finished product; the coarse and heavy particles fall down and are then collected at the coarse powder outlet of the lower cone and returned to the mill for re-grinding, thus forming a closed-loop system. Changing the rotor speed can effectively adjust the fineness of the finished product.