-

tel: +8617802596658

-

email: shpowderseparator@gmail.com

-

Whatsapp: 8617802599580

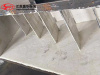

The Powder Selector Is Treated With Wear-Resistant Ceramics

The use of wear-resistant ceramics in the wear-resistant treatment of the powder separator is an advanced surface protection technology designed to improve the service life and wear-resistant performance of the powder separator. Wear-resistant ceramics have the advantages of high hardness, excellent wear resistance, light weight, strong bonding and good heat resistance. They can effectively resist the wear and impact of materials during the powder selection process.

Features of wear-resistant ceramics:

High hardness: The hardness of wear-resistant ceramics is second only to diamond, and far exceeds the wear resistance of wear-resistant steel and stainless steel.

Excellent wear resistance: It has been measured that its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high chromium cast iron, which can significantly extend the service life of the powder separator.

Light weight: The density of wear-resistant ceramics is only half that of steel, which helps reduce the load of the powder separator and improve operating efficiency.

Strong bonding: The wear-resistant ceramic sheets are bonded with high-strength ceramic structural adhesive to ensure that they will not fall off during long-term operation at high temperatures.

Application in wear-resistant treatment of powder separator:

Wear-resistant ceramics can be used on the inner walls of powder concentrators, impellers and other parts that are prone to wear, and can form a hard protective layer by pasting or spraying.

This protective layer can effectively resist the friction and impact caused by materials during the powder selection process, reduce the wear rate of the powder selector, and improve the stability and reliability of the equipment.

At the same time, the high-temperature resistance of wear-resistant ceramics enables it to adapt to the working needs of the powder separator in high-temperature environments, ensuring long-term stable operation of the equipment.

To sum up, using wear-resistant ceramics for the wear-resistant treatment of the powder separator is an efficient and reliable solution, which helps to improve the service life and wear-resistant performance of the powder separator.